|

| Homepage • Products • Contacts Us |

June - July 2010

First the good news. We are just about to ship the next velomobile # 23.

Now for the not quite so good news. We are stopping production of the Borealis until we are ready to do a new version. This will be version 2 which will see a new top that is a bit lower so the Borealis fits medium/small sized folks better. The new top will be about 5 cm lower which should remove the better part of a kilogram from the shell just by the reduction of the surface area. Some of the plugs are already underway but it looks as if a slightly new shape will be required for the door. I will have to build a new top nose section before we can start on the new door plug.

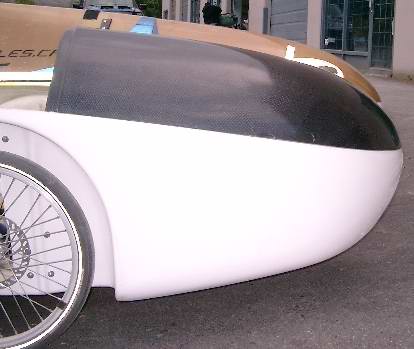

New steering setup is now available that allows us to leave more of the front wheel wells intact. The big benefit from doing this is that the front of the shell is now much stiffer. Doing this also lets us get rid of the front fenders and cloth covers that that closed off the wheel well. Here is a picture of the new cover installed. This one is laminated with basalt and carbon fiber.

The last three Borealis have had a new door that fits the Cycle Star mirrors. The bump in the door is lower as the mirror is a bit smalller diameter than the Norco mirror I was using originally. Norco discontinued their mirror and replaced with with an oval version that no longer fit my shape. The Cycle Star mirror while smaller is a better mirror and from using them both I prefer it over the old mirror. The new door shape helps with visibilty to the side and should be a bit more aerodynamic. When comparing the old and new door I like the look of the new one much better. Version two with this door shape and the lower profile of the whole top will look great. Be curoius to see if it is measurably faster.

Have been doing a fair bit of riding lately. Well at least for me anyway. The issue with riding more is finding the time. I did the Canada Day Populaire out of Fort Langley July 1st. There were two velomobiles on the ride. I managed to convince Brock from Cambie Cycles to bring his Borealis. It was much more fun to have another velomobile on the ride than last year when I wa the only one. I rode from home to the ride so I added some extra distance. It ended up being 172 km for the day. At first when I started out from home it felt like I was in for a long day. Spots where I normally do 33-38 kph were only at 26-28. Things improved a bit after I got warmed up but it still I still didn't feel quite normal. It did eventually catch up with me as the last 30 or so km were much slower than normal. All told it was still a fun ride in some nice countryside. I rode a bit the next two days but it took me until the third day to recover. If I wanted to did the Ride Over America next year it would be possible if I could ride about twice as much as now. For this year I should get in about 7,000 km.

July 17

Have been making good progress on the new moulds. Here are a couple of pictures of the new bow top section mould

This is the plug with gelcoat applied ready for layup.

The mould being wetsanded with 600 grit. I had to put gloves on for the sanding as I overdid it without them and had a couple of spots where the skin was almost sanded off and a bit tender. I hadn't intended to sand so much but had a bit of time between other jobs and it was nice out in front of the shop in the sunshine.

July 30

Have now built the new door mould and am ready to start sanding and polishing. Have made the new nose section in graphite and Innegra. Tried something new putting the first layer in and it seems to work. The part no longer has gelcoat on it and is lighter. If this technique works for the other parts this could save 2+ kgs on the weight of the shell. The only negative is that the parts will need to be painted with a clear coat as the material is right at the surface and will weather otherwise. From our experience with whitewater kayaks built much the same way the parts will last a long time they just do look so good after a few years. They can become itchy if you rub against the exposed fibers. Here are a couple of pictures of the new nose.

The new nose weighs 738 g while the nose on my velo weighs 900g. The standard production nose in kevlar is 1200g. The nose on my velo is a laminate of clear gel coat, one layer 207g glass cloth and one layer of 165g kevlar with a bit of reinforcing with some more kevlar. The new nose is one layer of 195 g carbon and one layer of 122g Innegra with some Innegra reinforcing. While the surface area is a bit less with the new nose the actual weight of the laminate is about the same. The reason for this is that Innegra's density is much less than that of kevlar and even with the 60+% fiber ratio the extra thickness soaks up enough resin to make it weigh about what 165g kevlar does. The big benefit with the Innegra is the structure is much more damage tolerant than one made of just graphite. Someone sat on the nose of my velomobile crushing the nose in for a good foot. I just popped it back out again and didn't get around to fixing it more almost 6 months. Had this been a graphite nose it might have been unrideable.

Set new record for the month in distance riden. Made to to 1028 km for July or just over 33 per day. . Normally about 600 so this is lots more. Rode mostly the Borealis but I also spent some time on the Strada. Bought some clipless pedals for it so now I may ride in a bit more. First and second trips with the clipless pedals proved challenging. Managed to only fall over twice. You get so used to not unclipping in the velomobile that its big change.

One observation about being clipped all the time in the velomobile is that I am across the interesection by the time most other riders have gotten rolling and clipped in. When this happens the extra mass the velomobile is not so much to deal with. From a rolling stop I do notice the weight more.

Been trying out new tires with some very positive results. Should have some to report on them next month.

Here are some pictures of the ventilation system.

The small

"L" shaped blocks held on with velcro hold the door open. I lost a

few until I teathered them on.

The small

"L" shaped blocks held on with velcro hold the door open. I lost a

few until I teathered them on.

Front of the door. At speed most of the time I just open the door at the back, then if that isn't not enough put the center block in. If its over 30 (85 F) I normally have all three in.

Showing how

open the whole side is. You r actually stick your hand out the side underthe

door. On long uphills this helps a bit to keep the grip shifter from getting

too slippery.

Showing how

open the whole side is. You r actually stick your hand out the side underthe

door. On long uphills this helps a bit to keep the grip shifter from getting

too slippery.

View from the back. You can vary the size of the opening by changing the placement of the block.